In the Zone: Choosing the right cable solution for each of your food preparation areas

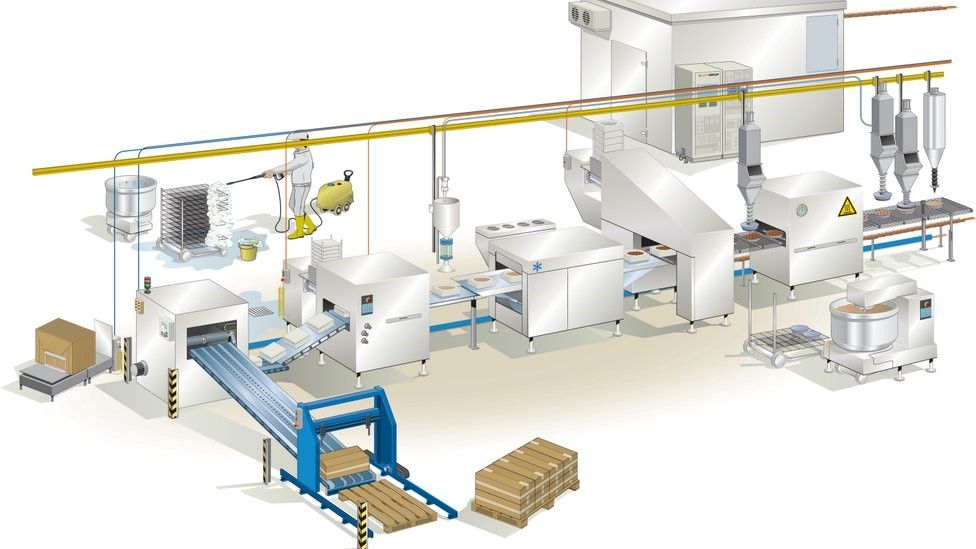

When it comes to food and beverage production, three main zones need to be taken into consideration – the Hygienic Design Zone, Splash Zone, and Non-Product Zone. Each of these areas has different external influences, such as mechanical or temperature variations.

To ensure the efficient and safe production of consumables, choosing the right cables and connection solutions for each of these zones is critical. Not only will this help minimize downtime and maintain quality, it also plays a major role in protecting employees.

So what factors should customers from the food and beverage industry bear in mind when selecting cable products for their production facilities? Here are some key elements to consider for each preparation zone:

Hygienic Design Zone requirements

The Hygienic Design Zone is where the highest hygiene standards are required. The cables, connectors, glands and other connectivity solutions used in this zone must meet stringent cleanliness regulations. They should be resistant to industrial cleaning agents and extreme temperature fluctuations, as they are often subjected to rigorous cleaning procedures involving steam and dry ice, to avoid contamination and ensure food safety.

Components used in this zone should be made of materials that are resistant to corrosion and microbial growth, and the cable design should eliminate hidden corners or crevices where food particles or bacteria might get lodged and result in contamination.

Choosing the right parts and cabling is crucial here for maintaining the highest level of hygiene and ensuring the quality and safety of the end product.

Splash Zone requirements

The Splash Zone is the area where food and beverage products are most likely to come into direct contact with the machinery. In this zone, cables and connection solutions need to meet specific safety requirements to prevent contamination and ensure product quality.

The cables used in this zone should be highly resistant to water, steam, cleaning agents, and other liquids. They should also be able to withstand the high-pressure cleaning methods typically used in the Splash Zone. The materials used in these cables should not absorb any liquids and should resist microbial growth to prevent contamination. The cables should also be robust enough to handle the mechanical stress present in this zone.

Non-Product Zone requirements

The Non-Product Zone is an area in the food and beverage production that does not come into direct contact with the food ingredients. A good example of the activities in this zone is the packaging and preparation for dispatch of the finished products.

Although it might seem less so, selecting the right cables for this zone is critical with regard to maintaining the overall safety and efficiency of the production environment.

In the Non-Product Zone, cables and connection solutions are primarily exposed to mechanical stresses rather than hygiene-related challenges. Therefore, the cables used in this zone should be robust and durable, capable of withstanding high levels of stress from vibrations, tension and flexing. Components should be designed for longevity and reliable performance, minimizing the risk of electrical faults, machine downtime and costly unscheduled repairs. Furthermore, they should be resistant to environmental factors, including temperature fluctuations, to continue to function optimally in a variety of conditions.

Selecting the appropriate cables and connection solutions for each specific zone in food and beverage production – the Hygienic Design Zone, the Splash Zone, and the Non-Product Zone – is of paramount importance. It directly influences the safety, efficiency and quality of your production process. One may say that the cables represent the arteries and veins, which supply electricity and data to the machinery, which represents the vital organs, all components of a system need to perform reliably.

At JJ-LAPP, we understand these unique requirements and challenges. We offer a comprehensive range of cable products that meet the distinct demands of each zone, from the highest hygiene standards to mechanical stress resilience. Our expertise in the industry, coupled with our commitment to quality and safety, makes us an essential partner for your cable solution needs.

For more information, please feel free to contact us at sales_jjls@jjsea.com or visit our e-shop